What are the characteristics of the component design of plastic ultrafiltration machine?

Ultrafiltration membrane assembly

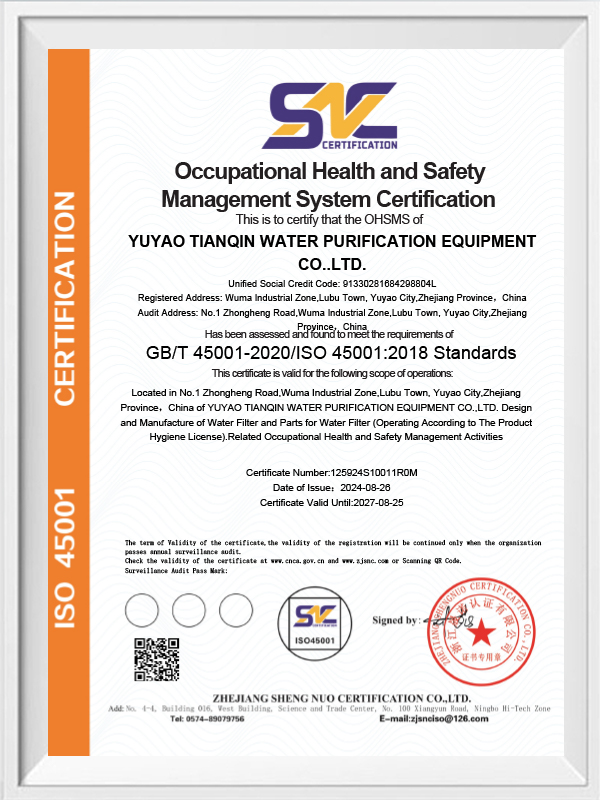

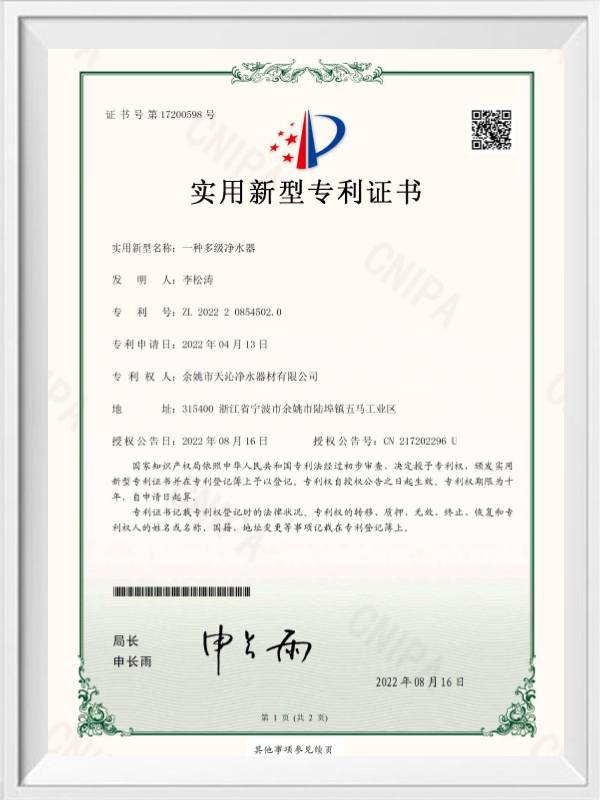

The ultrafiltration membrane assembly is the core part of the plastic ultrafiltration machine, and its performance directly affects the filtering effect of the equipment. Tianqin Water Purification Equipment uses cutting-edge membrane technology and precision manufacturing technology in the design of ultrafiltration membrane components to ensure the uniformity and stability of the membrane pore size. The ultrafiltration membrane independently developed by the company has superior characteristics such as high-efficiency interception, low energy consumption and long service life. It can effectively remove suspended matter, bacteria, viruses and some macromolecular organic matter in the water, thereby ensuring the safety and purity of the effluent water quality.

The component design also emphasizes the convenient cleaning and replacement characteristics. Users can easily disassemble and replace the membrane assembly according to actual needs. This design greatly reduces maintenance costs and time. This structure not only improves the reliability and stability of the equipment, but also provides users with a more convenient operating experience, further enhancing the overall use efficiency.

Modular design

Tianqin Water Purification Equipment incorporates the modular design concept into the component design of the plastic ultrafiltration machine. This design enables each component of the equipment to be disassembled and replaced independently, avoiding the tedious process of disassembling and reorganizing the entire machine. This structure not only improves the maintainability of the equipment, but also effectively reduces the maintenance cost and time.

Modular design also brings greater flexibility. Users can selectively upgrade or replace some modules according to actual needs to achieve continuous optimization and upgrading of the equipment. This design method not only meets the diverse needs of users, but also enhances the adaptability and market competitiveness of the equipment.

Intelligent control system

With the continuous advancement of intelligent technology, Tianqin Water Purification Equipment has also incorporated intelligent control systems into the component design of plastic ultrafiltration machines. The system has the ability to monitor the operating status, filtration effect and energy consumption of the equipment in real time, providing users with comprehensive data support.

The intelligent control system also has an automatic adjustment function, which can automatically adjust the filtration parameters according to changes in water quality and user needs. This design not only improves the filtration efficiency of the equipment, but also provides users with a more convenient use experience and further optimizes the operation process.

High-quality plastic material

In the selection of materials for plastic ultrafiltration machines, Tianqin Water Purification Equipment fully considers the durability and environmental protection of the equipment. The company uses high-quality plastic materials with excellent corrosion resistance, which can effectively resist the erosion of chemicals in the water, thereby extending the service life of the equipment.

At the same time, the lightweight characteristics of plastic materials make the installation and maintenance of the equipment easier. This design not only reduces the user's operating difficulty and cost, but also improves the reliability and stability of the equipment. In addition, Tianqin Water Purification Equipment pays attention to the concept of environmental protection in the production process, adopts advanced production technology and strict quality control system to ensure that each plastic ultrafiltration machine meets high quality standards and environmental protection requirements.

What is the operation process of plastic ultrafiltration machine

Before starting the plastic ultrafiltration machine, users need to carry out a series of necessary preparations to ensure the normal operation of the equipment and the safety of the effluent water quality. First, carefully check the various components of the equipment to ensure that the key components such as the ultrafiltration membrane assembly, the water inlet pipe and the water outlet pipe are installed intact, and there is no leakage at the connection. Next, open the water source valve to ensure that the water supply is sufficient and meets the water quality standards required by the equipment. In addition, be sure to confirm that the power switch of the equipment is in the off state to avoid unexpected situations during the startup process.

After completing the above preparations, users can start the plastic ultrafiltration machine. After pressing the power switch, the equipment will automatically enter the initialization stage. At this stage, the equipment will self-check each component, including the integrity of the ultrafiltration membrane assembly, the operating status of the water pump, and the sensitivity of the sensor. Users can monitor the initialization progress and status information in real time through the display screen of the equipment or the mobile phone application.

Tianqin Water Purification Equipment's plastic ultrafiltration machine is equipped with an intelligent control system that can automatically identify and adjust the operating status of the equipment. After initialization, the equipment will enter standby mode and wait for further operation by the user.

In order to meet the diverse needs of users, Tianqin Water Purification Equipment's plastic ultrafiltration machine provides a wealth of settings and operating parameter options. Users can personalize settings through the control panel of the equipment or the mobile phone application, including effluent water quality requirements, filtration mode and cleaning cycle. The setting of these parameters will directly affect the filtration effect and operating efficiency of the equipment.

After the settings are completed, the user can press the run button and the equipment will enter the formal working state. At this stage, the water pump will extract water from the water source, filter it through the ultrafiltration membrane assembly, and finally produce clean water that meets the requirements. At the same time, the equipment's sensors will monitor the effluent water quality and equipment operating status in real time to ensure the stability of the equipment and the safety of the effluent water quality.

In order to ensure the long-term stable operation of the plastic ultrafiltration machine and the continuous safety of the effluent water quality, users need to clean and maintain the equipment regularly. Tianqin Water Purification Equipment's plastic ultrafiltration machine adopts an intelligent cleaning system, which can automatically trigger the cleaning program according to the operating status of the equipment and the effluent water quality. During the cleaning process, the equipment will automatically stop filtering, start the cleaning water pump, and inject the cleaning liquid into the ultrafiltration membrane assembly for cleaning. After the cleaning is completed, the equipment will automatically resume filtering.

In addition to intelligent cleaning, users are also required to perform manual maintenance regularly, including replacing the filter element, checking whether the inlet and outlet pipes are blocked, and cleaning the equipment housing. These maintenance work will help improve the filtration efficiency of the equipment and extend its service life.

When the plastic ultrafiltration machine completes its work task or needs to be shut down for a long time, users should follow the correct shutdown and power-off process. First, press the stop button of the equipment, and the equipment will automatically stop filtering and turn off the water pump. Next, close the water source valve and cut off the water supply. Finally, press the power switch to power off the equipment and unplug the power cord. Following these steps will ensure the safe shutdown of the equipment and avoid potential safety hazards.

English

English 中文简体

中文简体