How to choose the filter element material of stainless steel water purifier

As an indispensable key component in the water treatment system, the choice of filter element material directly affects the water purification effect. Therefore, in-depth understanding of the basic characteristics of different filter element materials is the first step in choosing a suitable filter element. Common filter element materials include activated carbon, ceramics, ultrafiltration membranes and reverse osmosis membranes. Activated carbon can effectively remove residual chlorine, odor and some organic matter in water due to its excellent adsorption capacity. Ceramic filter elements can intercept suspended matter and microorganisms in water through physical filtration mechanisms. Ultrafiltration membrane filter elements have the ability to intercept bacteria, viruses and macromolecular organic matter, while reverse osmosis membranes can remove almost all pollutants in water with their extremely high filtration accuracy, including dissolved salts, colloids, microorganisms and heavy metal ions.

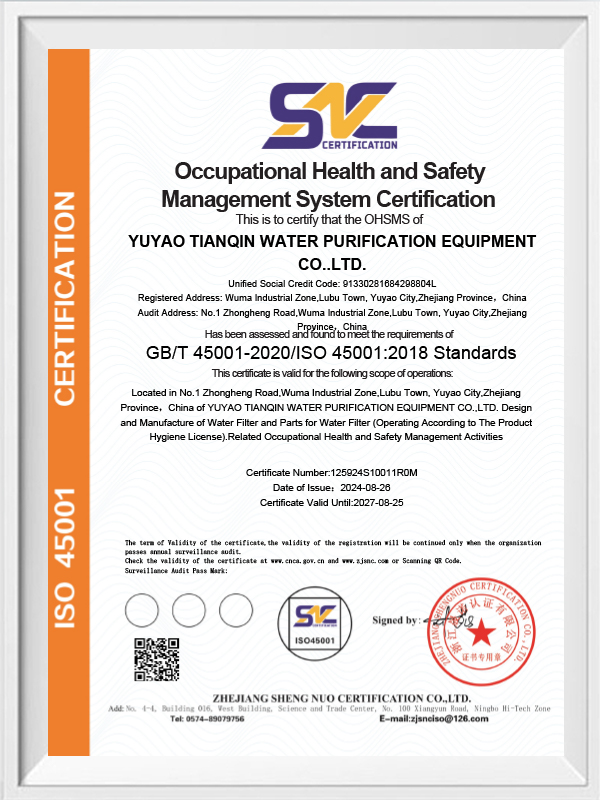

When choosing filter element materials, the characteristics of water quality must be considered. Tianqin Water Purification Equipment deeply realizes that the differences in water quality in different regions have a significant impact on the choice of filter element materials. Therefore, the company provides customized filter element material recommendations to adapt to the water quality characteristics of the user's area. For example, in areas with high residual chlorine content, activated carbon filters are recommended as the preferred choice; while in areas with hard water, reverse osmosis membrane filters are ideal for removing calcium and magnesium ions from water, effectively preventing the formation of scale.

The compatibility and durability of the filter element are also important considerations in the selection process. Tianqin Water Purification Equipment strictly conducts compatibility tests on the selection of filter element materials to ensure the perfect match between the filter element and other components of the stainless steel water purifier. At the same time, the company pays attention to the durability of the filter element and selects materials that can withstand high water pressure and are not easily deformed or damaged, thereby extending the service life of the filter element and reducing the user's maintenance costs.

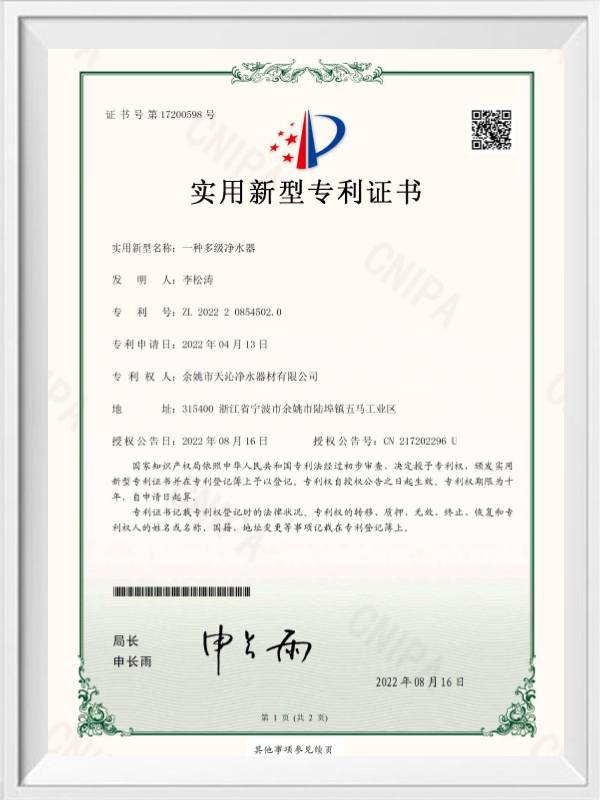

In order to continuously improve the purification effect of stainless steel water purifiers, Tianqin Water Purification Equipment continues to innovate in filter element materials and technologies. Through in-depth research, the R&D team has launched a series of new filter element materials, such as nano silver ion filter elements and activated carbon composite filter elements. These new filter elements not only have higher purification efficiency, but also effectively inhibit the growth of bacteria and improve the safety of water quality.

The maintenance and replacement of the filter element is also an important part of ensuring the continuous and efficient operation of the stainless steel water purifier. Tianqin Water Purification Equipment provides users with comprehensive filter maintenance guidance, including regular cleaning, backwashing and filter replacement and other operational suggestions. At the same time, the company has established a complete filter replacement reminder mechanism, using the intelligent monitoring system to monitor the service life of the filter in real time, and promptly remind users to replace it to ensure that the equipment is always in working condition.

What should be paid attention to when installing stainless steel water purifier

Preparation before installation

Before installing the stainless steel water purifier, users need to carefully confirm the installation location. The ideal installation environment should have a solid foundation and facilitate subsequent maintenance and maintenance. Users should conduct a comprehensive inspection of the equipment accessories to ensure that all components, including water pipes, joints and faucets, meet national health standards. In addition, turning off the main tap water switch is a necessary step to avoid safety hazards caused by water flow during installation.

Precautions during installation

Choose a suitable installation location

It is recommended that users install the stainless steel water purifier in a well-ventilated, dry area that avoids direct sunlight. This choice not only prevents bacteria from growing inside the equipment, but also effectively avoids material aging and corrosion caused by direct sunlight. At the same time, ensure that the equipment is away from heat sources to maintain its purification effect and extend its service life.

Connection of water pipes

When connecting water pipes, ensure the tightness of the connection to avoid water leakage. It is recommended to use PE pipes that meet food safety standards as connecting pipes to ensure the safety and purity of water quality. During the connection process, the use of auxiliary materials such as raw tape or sealing rubber rings can enhance the sealing of the connection and further reduce the risk of water leakage.

Installation of faucets

In order to facilitate users to take water, it is recommended to install a dedicated purification faucet. During installation, be sure to ensure that the faucet is firmly fixed to prevent shaking or falling off during use. At the same time, check whether the connection between the faucet and the water outlet of the equipment is tight to ensure that there is no water leakage.

Discharge of sewage

When installing a stainless steel water purifier, ensure that the sewage outlet can discharge sewage smoothly. It is recommended to connect the sewage pipe directly to the sewage pipe and leave appropriate space at the port to prevent sewage from flowing back into the equipment and affecting the purification effect.

Power-on and debugging

After the installation is completed, the user should turn on the power supply and perform power-on debugging of the equipment. During the debugging process, observe whether the equipment is running normally and check whether there is water leakage or seepage. It is recommended to place the equipment under observation for no less than two hours during the commissioning phase to ensure the stability and reliability of the equipment.

Maintenance and care after installation

After installation, regular maintenance and care of the stainless steel water purifier is the key to ensure its long-term and efficient operation. Users need to follow the requirements of the equipment manual and replace the filter element regularly to maintain the purification effect of the equipment. In addition, it is also necessary to clean the water pipes and faucets regularly to prevent bacterial growth and pipe blockage.

English

English 中文简体

中文简体