How does stainless steel pre-filter achieve efficient filtration

Precision filter media

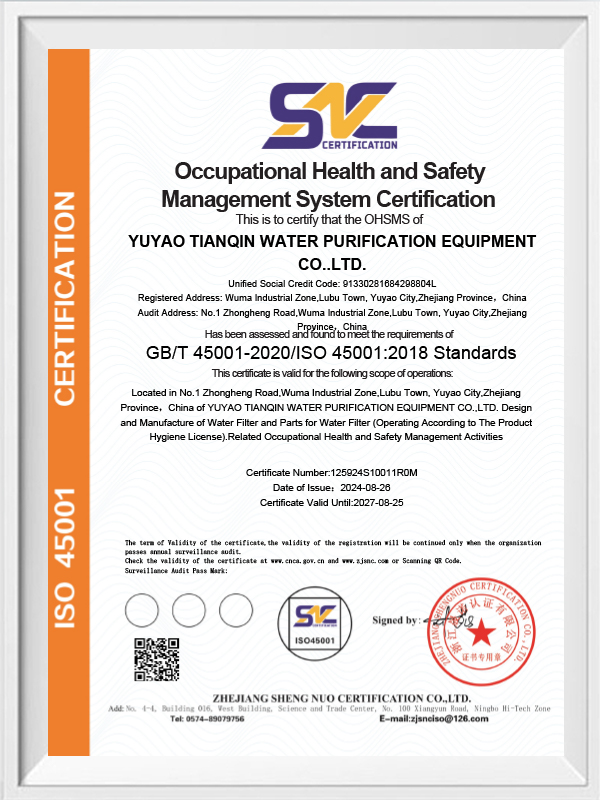

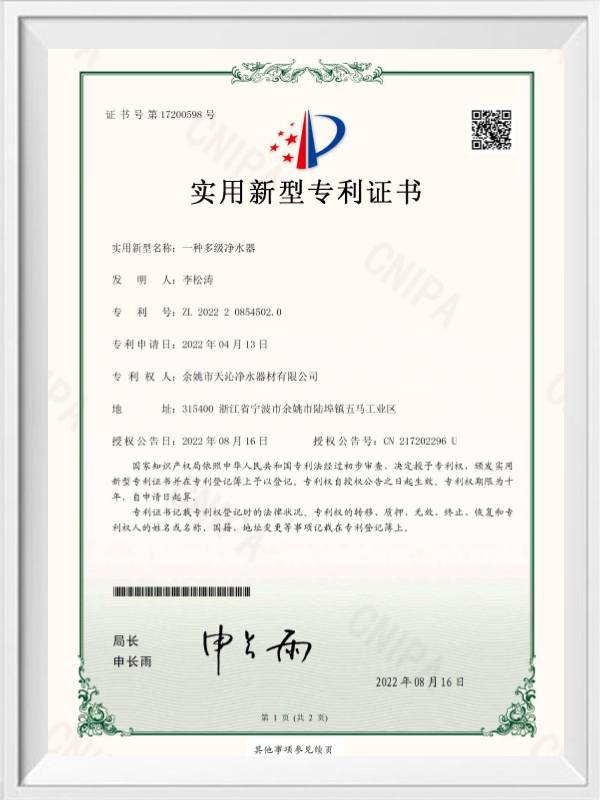

Yuyao Tianqin Water Purification Equipment Co..Ltd.'s stainless steel pre-filter uses multi-layer stainless steel sintered mesh and high-efficiency activated carbon filter element as the core filter media. The multi-layer stainless steel sintered mesh is made of metal meshes of different mesh sizes, forming a uniform and fine filter aperture, which can effectively remove large particle impurities, suspended matter and some organic matter in the water. This multi-layer structure not only improves the comprehensiveness of filtration, but also enhances the durability and stability of the filter. At the same time, the activated carbon filter element, with its excellent adsorption capacity, further removes residual chlorine, odor and some soluble organic matter in the water, significantly improving the safety and taste of water quality.

Unique structural design

The structural design of the stainless steel pre-filter plays a key role in its filtration efficiency. Yuyao Tianqin Water Purification Equipment uses advanced manufacturing technology to cleverly embed the filter medium into the filter housing to form a unique filtration channel. This design not only ensures the uniform distribution of water flow inside the filter, reduces the filtration resistance, but also expands the effective filtration area, thereby achieving higher filtration efficiency. In addition, the sealing performance of the shell is strictly controlled to ensure that no leakage occurs during the filtration process, further ensuring the safety of water quality.

Advanced filtration mechanism

The filtration mechanism of this stainless steel pre-filter includes three methods: inertial impact, interception and diffusion. When the water flows through the filter, large particles of impurities hit the filter medium due to inertia and are captured; medium-sized particles are effectively intercepted by the fibers or meshes of the filter medium; tiny particles spread along irregular paths through diffusion, increasing the chance of contact with the filter medium and thus being captured. Yuyao Tianqin Water Purification Equipment Co..Ltd.'s stainless steel pre-filter is based on these filtration mechanisms to achieve efficient removal of particles of different sizes and ensure excellent water quality.

Efficient backwash function

In order to maintain the continuous and efficient operation of the filter, Yuyao Tianqin Water Purification Equipment Co..Ltd. is equipped with an advanced backwash function for its stainless steel pre-filter. When the impurities accumulated inside the filter reach a certain level, the system will automatically start the backwash program, flush the impurities out of the filter through reverse water flow, and quickly restore its filtration capacity.

What should be paid attention to in the installation and maintenance of stainless steel pre-filter

Installation precautions

Before installing the stainless steel pre-filter, a comprehensive inspection and preparation must be carried out. First, confirm the integrity of all equipment components to ensure that there is no damage or deformation. At the same time, carefully read the product manual to understand the performance parameters of the equipment and its installation requirements. It is crucial to choose a suitable installation location, and ensure that there is enough space at the location for subsequent operation, maintenance and repair.

When choosing the installation location, the weight and size of the filter must be considered comprehensively to ensure that the installation foundation can withstand its load. In addition, avoid installing the equipment in a heat source or humid environment to avoid potential damage to the equipment. For the stainless steel pre-filter produced by our company (Yuyao Tianqin Water Purification Equipment Co..Ltd.), its design is reasonable and its structure is compact. It can adapt to a variety of installation environments and provide flexible options.

In terms of pipeline connection, it is necessary to ensure that the size of the inlet and outlet pipes matches the filter interface, and select suitable seals and connectors to ensure the tightness and leakage of the connection. Before connecting, the pipeline needs to be thoroughly cleaned to remove internal impurities and rust to avoid affecting the normal operation and service life of the filter.

The correctness of the installation direction should not be ignored. It is necessary to follow the markings on the filter to ensure the accuracy of the inlet and outlet directions and avoid reverse installation. Reverse installation may lead to poor filtering effect or equipment damage.

In the fixing and debugging stage, the filter should be firmly fixed to the installation foundation with anchor bolts or other fixing devices to prevent shaking or displacement during operation. After the installation is completed, the sealing of each connection part of the filter should be checked. It is recommended to use soapy water or other leak detection methods. Before it is officially put into use, a trial run is carried out to observe the operating status of the filter to ensure that there is no abnormal sound or leakage.

Maintenance points

Regular inspection of the stainless steel pre-filter is an important part of ensuring its normal operation. During regular inspections, focus on the appearance of the filter to check whether there are problems such as corrosion, deformation or damage. At the same time, monitor the pressure difference between the inlet and outlet of the filter. When the pressure difference exceeds the specified value, it indicates that the filter may be blocked. At this time, it is necessary to clean or replace the filter element in time.

The cleaning and replacement of the filter element should be formulated according to the use of the filter and the water quality. During the cleaning process, the filter element can be removed from the filter and rinsed with clean water or treated with a special cleaning agent. For some impurities that are difficult to clean, ultrasonic cleaning and other methods are effective options. After cleaning, make sure the filter element is completely dry before installing it back into the filter. In addition, after a period of use, the filter element's filtering performance will gradually decline, so it needs to be replaced in time to ensure the stability of the filtering effect.

For situations where the inside of the filter is exposed to corrosive media, it is recommended to apply anti-corrosion paint or use corrosion-resistant materials for lining the inside of the filter, which can effectively extend the service life of the equipment and ensure its reliability and stability in various environments.

English

English 中文简体

中文简体