-

UV11W High-efficiency Intelligent UV Water Sterilizer Cat:Ultraviolet Water Sterilizer

UV11W High-efficiency Intelligent UV Water Sterilizer Cat:Ultraviolet Water SterilizerThe UV11W High-efficiency Intelligent UV Water Sterilizer is an advanced water purification system that offers convenience and reliability. This steri...

See Details -

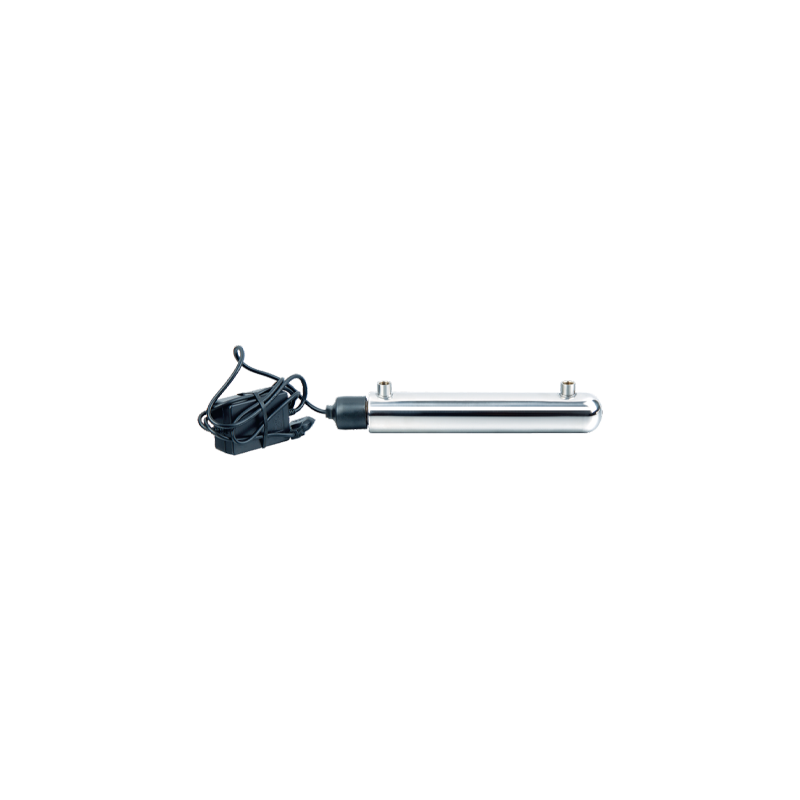

UV16W-A Household Stainless Steel UV Water Sterilizer Cat:Ultraviolet Water Sterilizer

UV16W-A Household Stainless Steel UV Water Sterilizer Cat:Ultraviolet Water SterilizerThe UV16W-A Household Stainless Steel UV Water Sterilizer is an innovative solution for ensuring safe and pure water in your home. Designed with durab...

See Details -

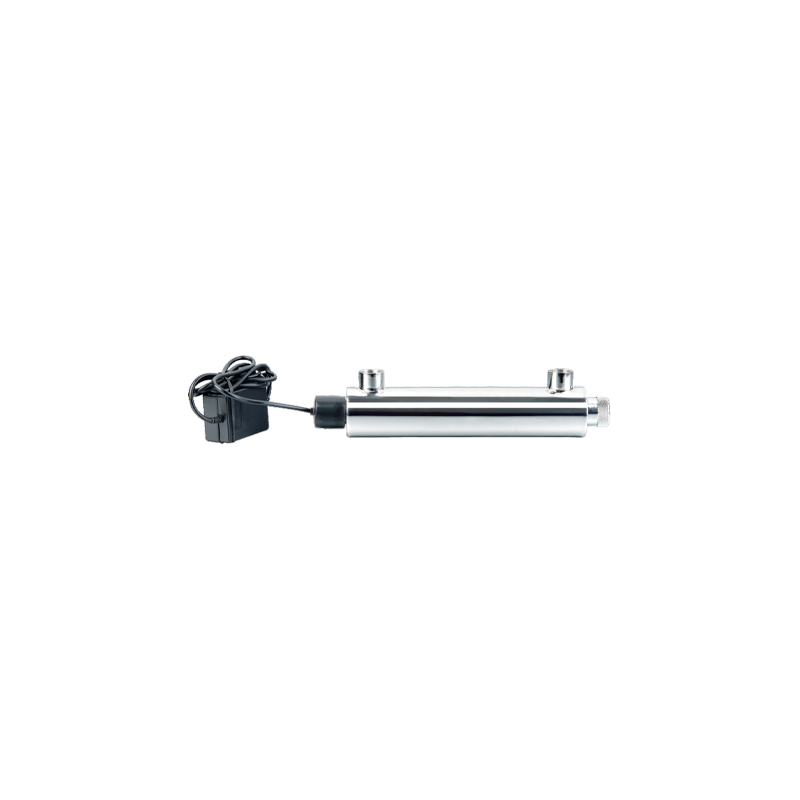

UV16W-B 304 Stainless Steel Water Purifier Ultraviolet Water Sterilizer Cat:Ultraviolet Water Sterilizer

UV16W-B 304 Stainless Steel Water Purifier Ultraviolet Water Sterilizer Cat:Ultraviolet Water SterilizerUV16W-B 304 Stainless Steel Water Purifier Ultraviolet Water Sterilizer is an efficient water treatment equipment based on advanced ultraviolet disinf...

See Details -

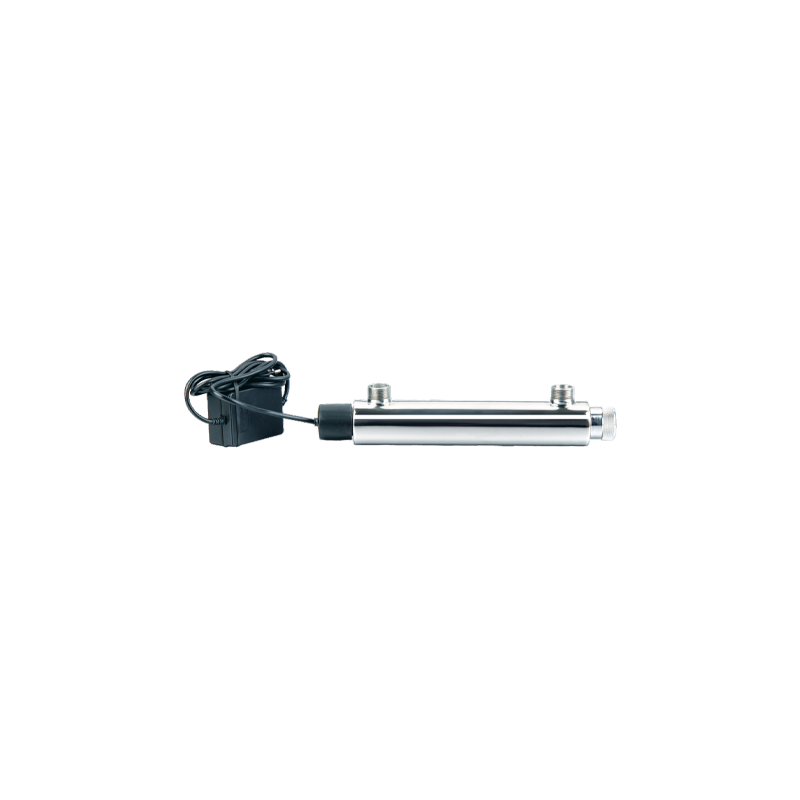

UV25W Stainless Steel Ultrafiltration Pre-Filtration UV Sterilizers For Water Cat:Ultraviolet Water Sterilizer

UV25W Stainless Steel Ultrafiltration Pre-Filtration UV Sterilizers For Water Cat:Ultraviolet Water SterilizerUV25W Stainless Steel Ultrafiltration Pre-Filtration UV Sterilizers For Water uses high-quality stainless steel materials, which have superb corrosion...

See Details -

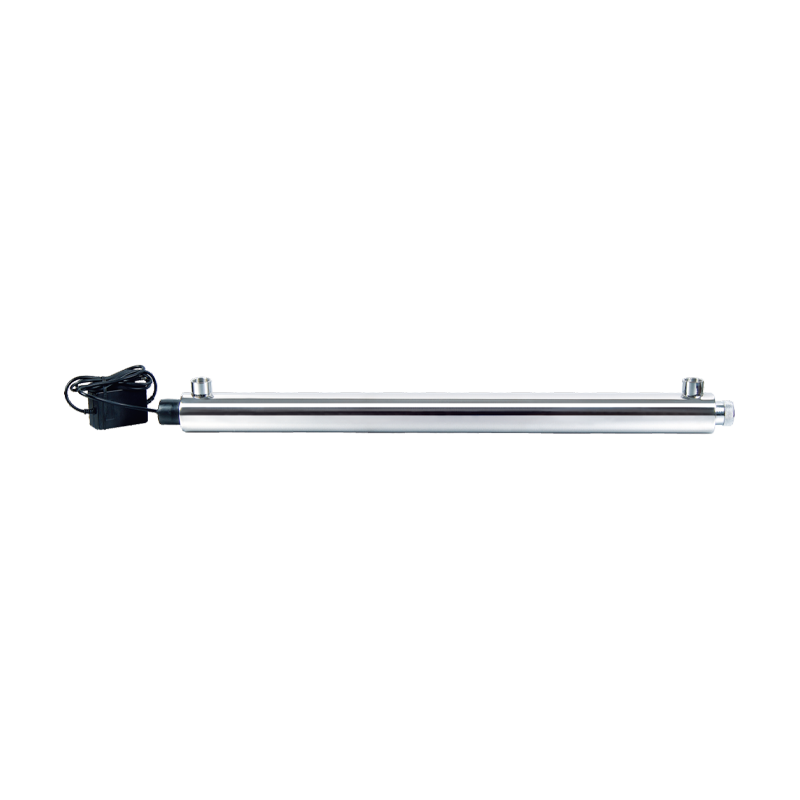

UV30W-55W Automatic Ultraviolet Sterilizer UV Filtration For Drinking Water Cat:Ultraviolet Water Sterilizer

UV30W-55W Automatic Ultraviolet Sterilizer UV Filtration For Drinking Water Cat:Ultraviolet Water SterilizerThe core advantage of UV30W-55W Automatic Ultraviolet Sterilizer UV Filtration For Drinking Water lies in its efficient and rapid disinfection capabil...

See Details -

TQ-R03 Stainless Steel Booster Double Water Full Effect RO Water Purifier Cat:Stainless Steel Ro System

TQ-R03 Stainless Steel Booster Double Water Full Effect RO Water Purifier Cat:Stainless Steel Ro SystemTQ-R03 Stainless Steel Booster Double Water Full Effect RO Water Purifier is a household water purification device that combines efficient water purif...

See Details -

TQ-R05 Multifunctional Water Purification Source RO Water Purifier Cat:Stainless Steel Ro System

TQ-R05 Multifunctional Water Purification Source RO Water Purifier Cat:Stainless Steel Ro SystemThe TQ-R05 Multifunctional Water Purification Source RO Water Purifier is an advanced, versatile water purification solution designed for households a...

See Details -

TQ-R06 Stainless Steel Environmentally Friendly RO Water Purifier Cat:Stainless Steel Ro System

TQ-R06 Stainless Steel Environmentally Friendly RO Water Purifier Cat:Stainless Steel Ro SystemThe TQ-R06 Stainless Steel Environmentally Friendly RO Water Purifier combines advanced RO filtration technology, durable stainless steel housing, and...

See Details -

Stainless Steel Pure Double Water Pipe Water Purifier Cat:Stainless Steel Pipeline Water Purifier

Stainless Steel Pure Double Water Pipe Water Purifier Cat:Stainless Steel Pipeline Water PurifierThe Stainless Steel Pure Double Water Pipe Water Purifier is an advanced water purification system designed to provide dual-mode purified water with e...

See Details -

TQ-R08 Stainless Steel High-Flow RO Water Filter Cat:Stainless Steel Ro System

TQ-R08 Stainless Steel High-Flow RO Water Filter Cat:Stainless Steel Ro SystemThe Stainless Steel High-Flow RO Water Filter (TQ-R08) provides a powerful and effective solution for purifying drinking water, combining advanced rev...

See Details

How does the internal filtration system of a stainless steel water purifier prevent bacterial growth and contamination over time

The use of anti-microbial materials is one of the primary defenses against bacterial growth in a stainless steel water purifier. Certain filters and components, such as activated carbon or ceramic elements, may be infused with anti-bacterial agents like silver or copper. Silver ions, for example, are known for their natural ability to inhibit the growth of bacteria and other pathogens. The inclusion of these anti-microbial agents ensures that bacteria cannot thrive within the filter media or on the surfaces that come into contact with water. Over time, these materials help maintain the cleanliness of the system, preventing contamination that could compromise the effectiveness of the filtration process.

Stainless steel itself contributes significantly to the purity of water in the system. Unlike other materials, such as plastic or copper, stainless steel is non-porous and resistant to corrosion. Its smooth, polished surface prevents bacterial attachment and reduces the chances of microbial proliferation. Stainless steel is also highly durable, which ensures that the purifier maintains its performance over the long term. It does not leach harmful chemicals or toxins into the water, making it ideal for maintaining a hygienic environment within the system. This ensures that the water stays free from contaminants even as the purifier is used consistently over time.

Ultraviolet (UV) sterilization technology is widely regarded as one of the most effective ways to eliminate harmful microorganisms in water. Many stainless steel water purifiers incorporate UV lamps that emit UV-C light, which disrupts the DNA of bacteria, viruses, and other pathogens, rendering them unable to reproduce or cause illness. UV sterilization provides an added layer of protection after the initial filtration process, ensuring that even trace amounts of bacteria are effectively neutralized. This technology is particularly beneficial in maintaining the purity of the water as it passes through the purifier and reducing the risk of bacterial growth within the system.

Activated carbon plays a critical role in removing organic contaminants and impurities that could foster bacterial growth. The porous surface of activated carbon adsorbs chlorine, chemicals, and various organic compounds from the water. This reduces the potential for bacterial growth by removing the food sources that would otherwise promote microbial activity. Activated carbon helps improve the taste and odor of the water, which is an added benefit for users. Some advanced activated carbon filters may also be treated with additional anti-bacterial agents to enhance their ability to reduce microbial contamination.

Sediment pre-filters are typically the first stage of filtration in a stainless steel water purifier. These filters remove larger particles, such as dirt, sand, and debris, from the water before it moves to more refined filtration stages. By trapping these larger contaminants, the sediment pre-filter reduces the likelihood of organic matter accumulating in the system, which could serve as a breeding ground for bacteria. With fewer particles in the water, the filtration process becomes more efficient, and the risk of contamination is minimized. Cleaner system reduces the strain on subsequent filters, ensuring longer lifespan and optimal performance.

To prevent stagnant water, which is a common cause of bacterial growth, many stainless steel water purifiers are designed to ensure a continuous flow of water through the system. Stagnation can lead to an accumulation of organic materials and promote microbial activity. By maintaining constant water movement, these purifiers ensure that the water does not remain in one place long enough to foster bacteria. This dynamic flow is crucial for preventing microbial growth, especially in areas like the storage tank or filter housing where water can sit if the flow is inadequate.

English

English 中文简体

中文简体