-

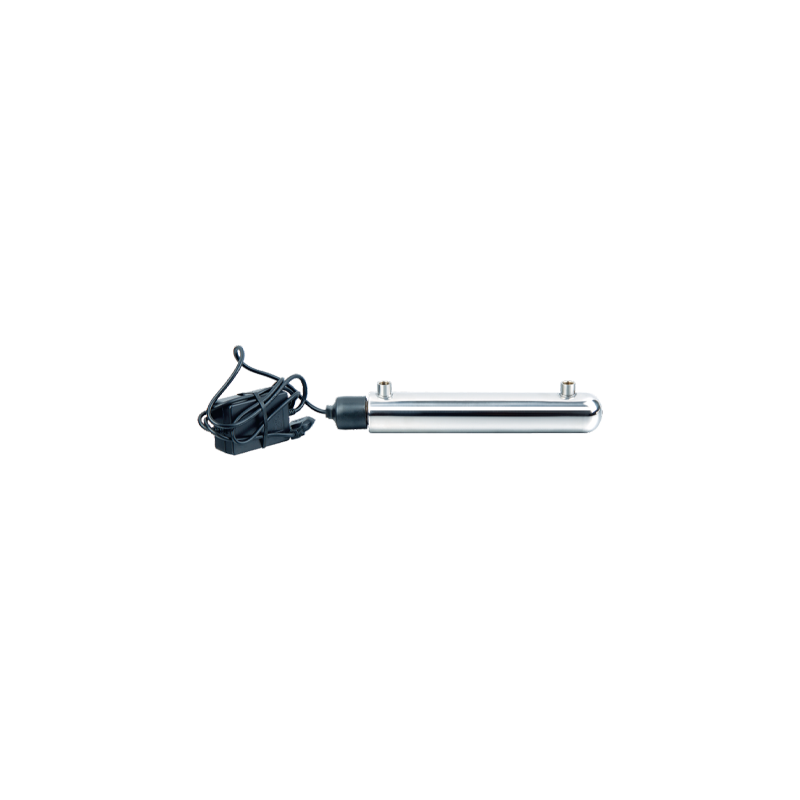

UV11W High-efficiency Intelligent UV Water Sterilizer Cat:Ultraviolet Water Sterilizer

UV11W High-efficiency Intelligent UV Water Sterilizer Cat:Ultraviolet Water SterilizerThe UV11W High-efficiency Intelligent UV Water Sterilizer is an advanced water purification system that offers convenience and reliability. This steri...

See Details -

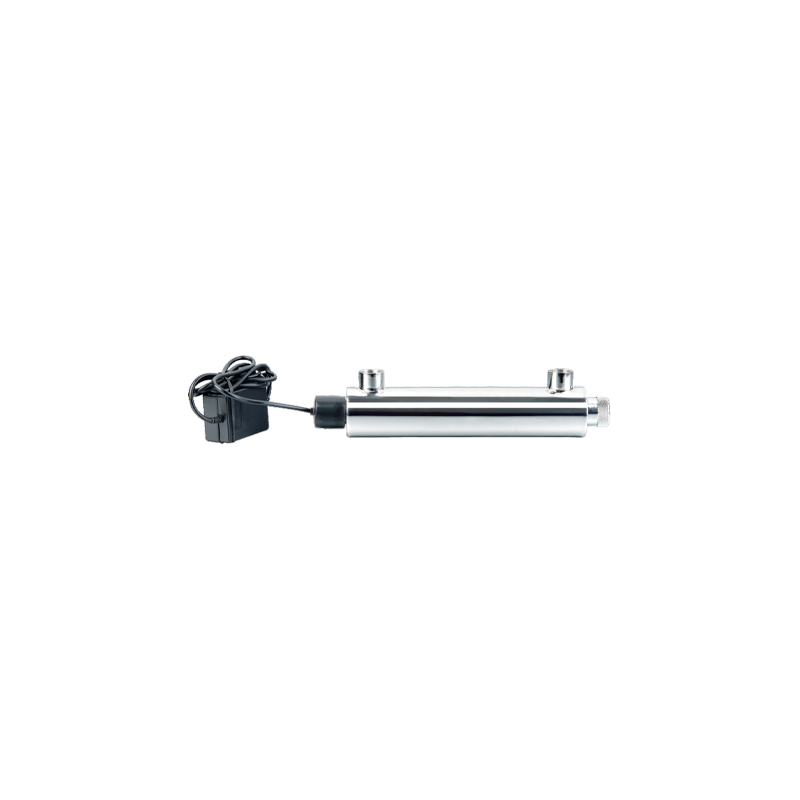

UV16W-A Household Stainless Steel UV Water Sterilizer Cat:Ultraviolet Water Sterilizer

UV16W-A Household Stainless Steel UV Water Sterilizer Cat:Ultraviolet Water SterilizerThe UV16W-A Household Stainless Steel UV Water Sterilizer is an innovative solution for ensuring safe and pure water in your home. Designed with durab...

See Details -

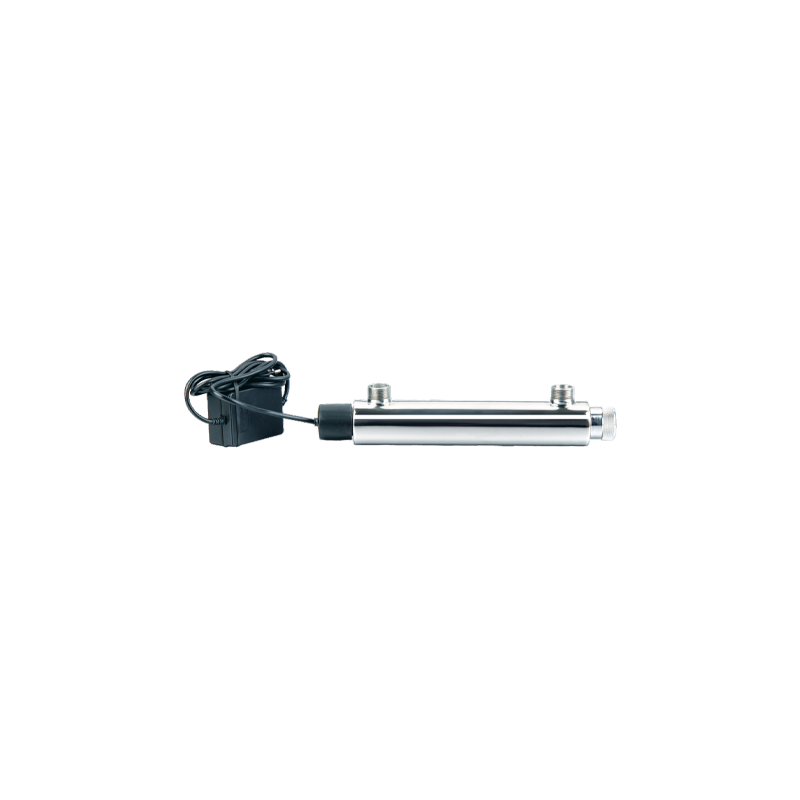

UV16W-B 304 Stainless Steel Water Purifier Ultraviolet Water Sterilizer Cat:Ultraviolet Water Sterilizer

UV16W-B 304 Stainless Steel Water Purifier Ultraviolet Water Sterilizer Cat:Ultraviolet Water SterilizerUV16W-B 304 Stainless Steel Water Purifier Ultraviolet Water Sterilizer is an efficient water treatment equipment based on advanced ultraviolet disinf...

See Details -

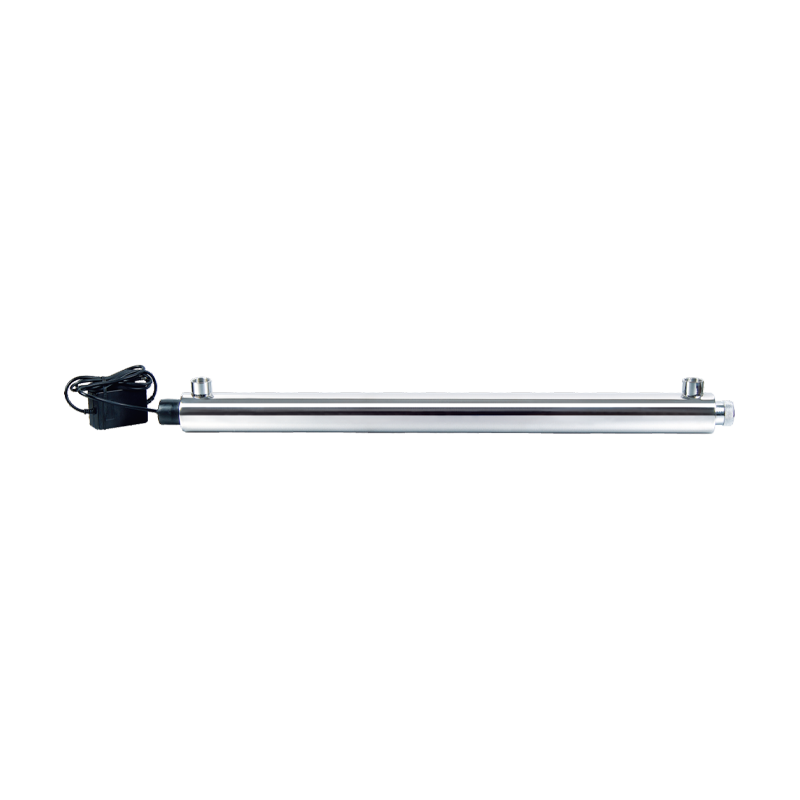

UV25W Stainless Steel Ultrafiltration Pre-Filtration UV Sterilizers For Water Cat:Ultraviolet Water Sterilizer

UV25W Stainless Steel Ultrafiltration Pre-Filtration UV Sterilizers For Water Cat:Ultraviolet Water SterilizerUV25W Stainless Steel Ultrafiltration Pre-Filtration UV Sterilizers For Water uses high-quality stainless steel materials, which have superb corrosion...

See Details -

UV30W-55W Automatic Ultraviolet Sterilizer UV Filtration For Drinking Water Cat:Ultraviolet Water Sterilizer

UV30W-55W Automatic Ultraviolet Sterilizer UV Filtration For Drinking Water Cat:Ultraviolet Water SterilizerThe core advantage of UV30W-55W Automatic Ultraviolet Sterilizer UV Filtration For Drinking Water lies in its efficient and rapid disinfection capabil...

See Details -

TQ-R03 Stainless Steel Booster Double Water Full Effect RO Water Purifier Cat:Stainless Steel Ro System

TQ-R03 Stainless Steel Booster Double Water Full Effect RO Water Purifier Cat:Stainless Steel Ro SystemTQ-R03 Stainless Steel Booster Double Water Full Effect RO Water Purifier is a household water purification device that combines efficient water purif...

See Details -

TQ-R05 Multifunctional Water Purification Source RO Water Purifier Cat:Stainless Steel Ro System

TQ-R05 Multifunctional Water Purification Source RO Water Purifier Cat:Stainless Steel Ro SystemThe TQ-R05 Multifunctional Water Purification Source RO Water Purifier is an advanced, versatile water purification solution designed for households a...

See Details -

TQ-R06 Stainless Steel Environmentally Friendly RO Water Purifier Cat:Stainless Steel Ro System

TQ-R06 Stainless Steel Environmentally Friendly RO Water Purifier Cat:Stainless Steel Ro SystemThe TQ-R06 Stainless Steel Environmentally Friendly RO Water Purifier combines advanced RO filtration technology, durable stainless steel housing, and...

See Details -

Stainless Steel Pure Double Water Pipe Water Purifier Cat:Stainless Steel Pipeline Water Purifier

Stainless Steel Pure Double Water Pipe Water Purifier Cat:Stainless Steel Pipeline Water PurifierThe Stainless Steel Pure Double Water Pipe Water Purifier is an advanced water purification system designed to provide dual-mode purified water with e...

See Details -

TQ-R08 Stainless Steel High-Flow RO Water Filter Cat:Stainless Steel Ro System

TQ-R08 Stainless Steel High-Flow RO Water Filter Cat:Stainless Steel Ro SystemThe Stainless Steel High-Flow RO Water Filter (TQ-R08) provides a powerful and effective solution for purifying drinking water, combining advanced rev...

See Details

How does the stainless steel water purifier handle varying water pressure levels to maintain consistent filtration performance

Stainless steel water purifiers are often equipped with pressure-regulated valves that help manage fluctuations in water pressure. These valves are designed to regulate the pressure within the ideal operational range for optimal filtration. For instance, when water pressure exceeds the recommended level, the valve will release excess pressure, preventing damage to internal components and ensuring that the filter operates efficiently. Likewise, in the event of low water pressure, these valves help maintain a constant flow rate that is suitable for effective filtration.

In response to varying pressure levels, stainless steel water purifiers often feature adjustable flow rate systems. These systems are designed to optimize the flow of water through the filters, ensuring that the filtration media (such as activated carbon, reverse osmosis membranes, or sediment filters) has adequate time to remove contaminants. Even if the pressure varies, the flow rate can be adjusted to accommodate these changes. In some models, the purifier’s flow control system automatically adapts to maintain a steady, appropriate flow rate, ensuring that the filtration process is neither too fast (which might reduce effectiveness) nor too slow (which could lead to inefficiency).

Stainless steel water purifiers incorporate a multi-stage filtration system that is capable of adjusting to varying water pressures. By using multiple layers of filters, including sediment filters, activated carbon filters, and perhaps even UV sterilization, the system is designed to perform effectively regardless of fluctuations in pressure. These multiple stages work synergistically to ensure that contaminants are removed thoroughly even if the pressure fluctuates. For instance, sediment filters may trap larger particles before the water moves to finer filters, while activated carbon removes chemicals and impurities that may not be captured in the initial stages.

The internal components of stainless steel water purifiers are designed to withstand different water pressure levels. High-quality stainless steel construction ensures that the filter housing and connectors are durable and resistant to corrosion, pressure, and wear over time. The durability of the components ensures that the purifier maintains its structural integrity, even under conditions that might damage lower-quality plastic or composite materials. The use of stainless steel enhances the reliability of the entire system, providing long-term, trouble-free operation.

Advanced stainless steel water purifiers often feature built-in automatic pressure monitoring systems. These systems continuously track the incoming water pressure and adjust the filter’s operation in real-time. If the pressure drops too low, the system might slow the flow or adjust the filtration process to maintain effective treatment. Similarly, when the pressure is too high, the purifier may reduce the flow rate to avoid overloading the system or damaging the filter. By automatically responding to changes in pressure, the purifier ensures that the water treatment process remains stable and reliable regardless of external pressure fluctuations.

Some of the more sophisticated stainless steel water purifiers utilize pressure compensation technology. This feature detects variations in incoming water pressure and automatically compensates for those changes, ensuring consistent filtration performance. For example, if there is a sudden drop in water pressure, the system will adapt by adjusting the filtration process to continue delivering clean water. Conversely, if the pressure spikes unexpectedly, the technology can reduce the flow rate or divert excess pressure to protect the filter and other internal components from damage. This compensation ensures the long-term durability and efficiency of the purifier, even under challenging conditions.

English

English 中文简体

中文简体