-

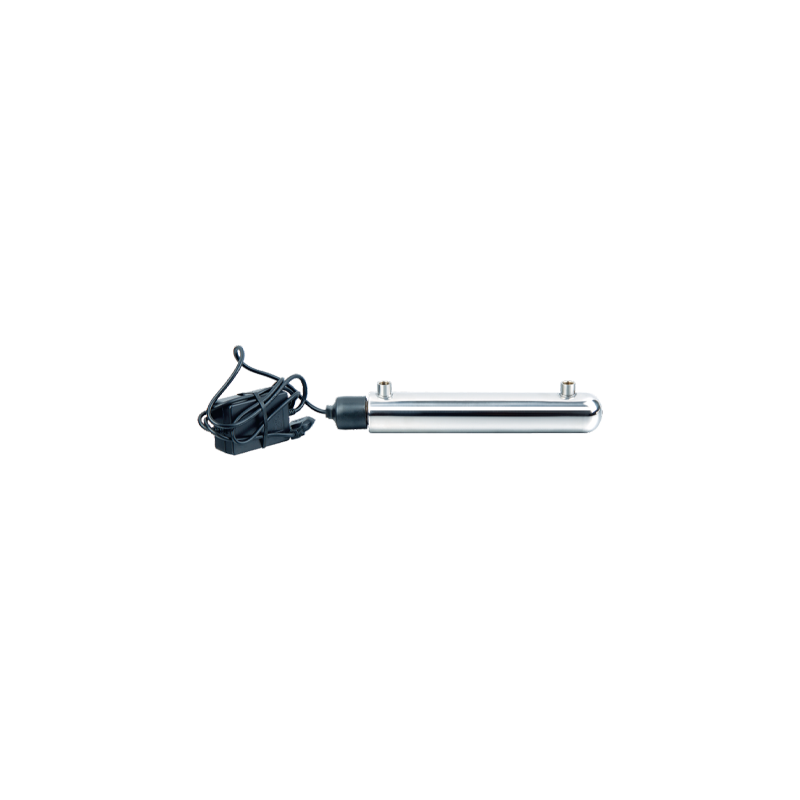

UV11W High-efficiency Intelligent UV Water Sterilizer Cat:Ultraviolet Water Sterilizer

UV11W High-efficiency Intelligent UV Water Sterilizer Cat:Ultraviolet Water SterilizerThe UV11W High-efficiency Intelligent UV Water Sterilizer is an advanced water purification system that offers convenience and reliability. This steri...

See Details -

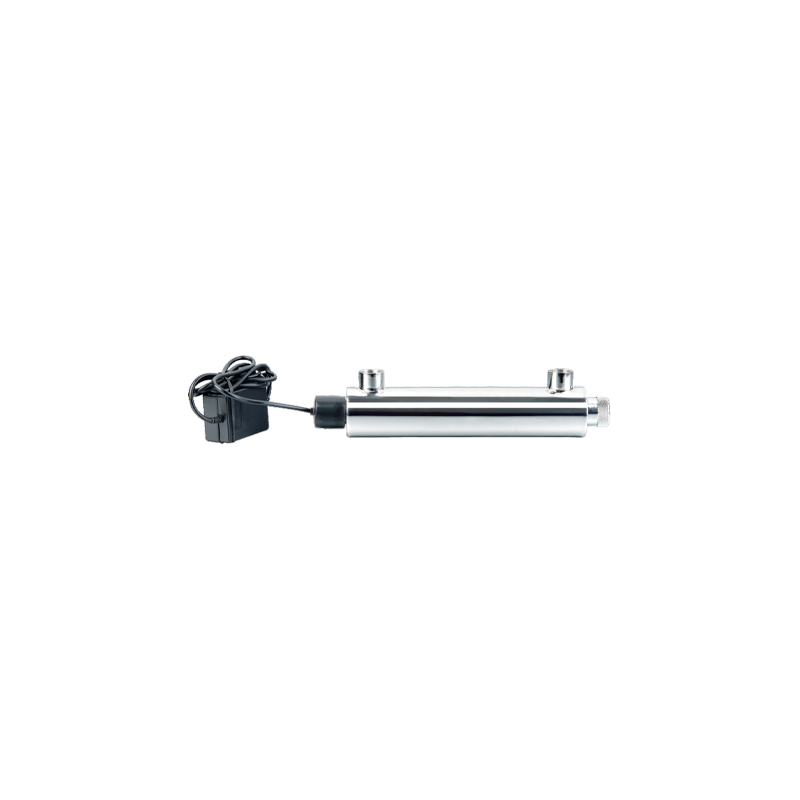

UV16W-A Household Stainless Steel UV Water Sterilizer Cat:Ultraviolet Water Sterilizer

UV16W-A Household Stainless Steel UV Water Sterilizer Cat:Ultraviolet Water SterilizerThe UV16W-A Household Stainless Steel UV Water Sterilizer is an innovative solution for ensuring safe and pure water in your home. Designed with durab...

See Details -

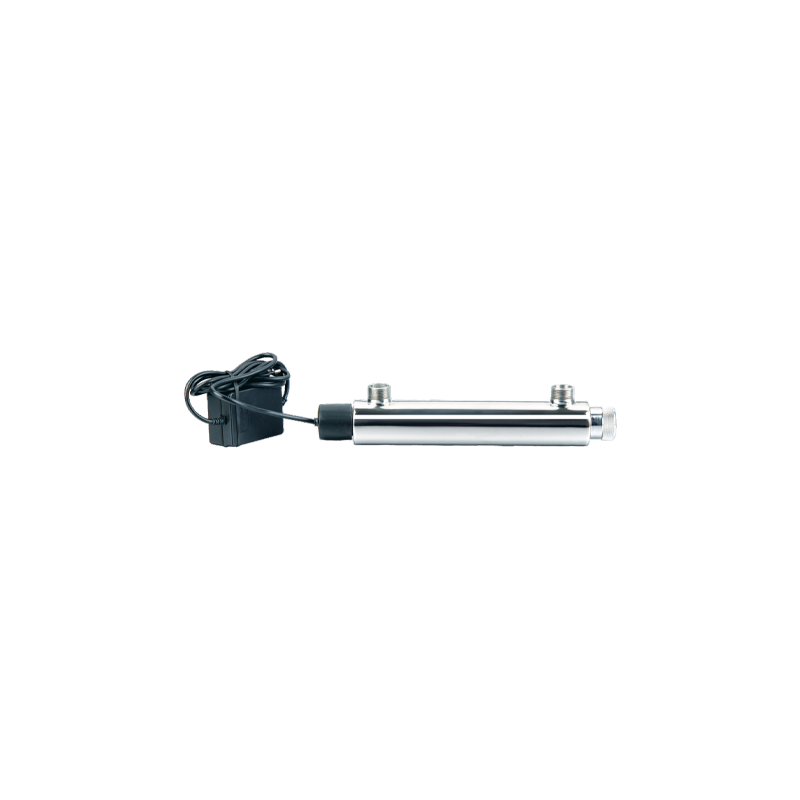

UV16W-B 304 Stainless Steel Water Purifier Ultraviolet Water Sterilizer Cat:Ultraviolet Water Sterilizer

UV16W-B 304 Stainless Steel Water Purifier Ultraviolet Water Sterilizer Cat:Ultraviolet Water SterilizerUV16W-B 304 Stainless Steel Water Purifier Ultraviolet Water Sterilizer is an efficient water treatment equipment based on advanced ultraviolet disinf...

See Details -

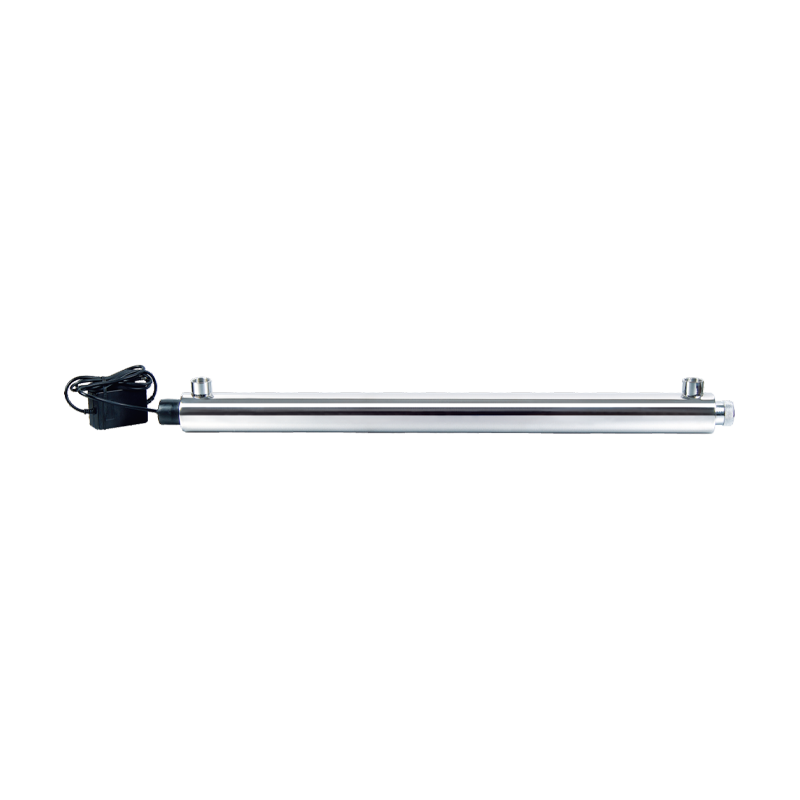

UV25W Stainless Steel Ultrafiltration Pre-Filtration UV Sterilizers For Water Cat:Ultraviolet Water Sterilizer

UV25W Stainless Steel Ultrafiltration Pre-Filtration UV Sterilizers For Water Cat:Ultraviolet Water SterilizerUV25W Stainless Steel Ultrafiltration Pre-Filtration UV Sterilizers For Water uses high-quality stainless steel materials, which have superb corrosion...

See Details -

UV30W-55W Automatic Ultraviolet Sterilizer UV Filtration For Drinking Water Cat:Ultraviolet Water Sterilizer

UV30W-55W Automatic Ultraviolet Sterilizer UV Filtration For Drinking Water Cat:Ultraviolet Water SterilizerThe core advantage of UV30W-55W Automatic Ultraviolet Sterilizer UV Filtration For Drinking Water lies in its efficient and rapid disinfection capabil...

See Details -

TQ-R03 Stainless Steel Booster Double Water Full Effect RO Water Purifier Cat:Stainless Steel Ro System

TQ-R03 Stainless Steel Booster Double Water Full Effect RO Water Purifier Cat:Stainless Steel Ro SystemTQ-R03 Stainless Steel Booster Double Water Full Effect RO Water Purifier is a household water purification device that combines efficient water purif...

See Details -

TQ-R05 Multifunctional Water Purification Source RO Water Purifier Cat:Stainless Steel Ro System

TQ-R05 Multifunctional Water Purification Source RO Water Purifier Cat:Stainless Steel Ro SystemThe TQ-R05 Multifunctional Water Purification Source RO Water Purifier is an advanced, versatile water purification solution designed for households a...

See Details -

TQ-R06 Stainless Steel Environmentally Friendly RO Water Purifier Cat:Stainless Steel Ro System

TQ-R06 Stainless Steel Environmentally Friendly RO Water Purifier Cat:Stainless Steel Ro SystemThe TQ-R06 Stainless Steel Environmentally Friendly RO Water Purifier combines advanced RO filtration technology, durable stainless steel housing, and...

See Details -

Stainless Steel Pure Double Water Pipe Water Purifier Cat:Stainless Steel Pipeline Water Purifier

Stainless Steel Pure Double Water Pipe Water Purifier Cat:Stainless Steel Pipeline Water PurifierThe Stainless Steel Pure Double Water Pipe Water Purifier is an advanced water purification system designed to provide dual-mode purified water with e...

See Details -

TQ-R08 Stainless Steel High-Flow RO Water Filter Cat:Stainless Steel Ro System

TQ-R08 Stainless Steel High-Flow RO Water Filter Cat:Stainless Steel Ro SystemThe Stainless Steel High-Flow RO Water Filter (TQ-R08) provides a powerful and effective solution for purifying drinking water, combining advanced rev...

See Details

How do stainless steel reverse osmosis systems improve water treatment efficiency

Stainless steel reverse osmosis (RO) systems have significant advantages in the water treatment industry and can significantly improve water treatment efficiency. These systems combine reverse osmosis membrane technology with the high efficiency of stainless steel materials and are widely used in various industrial and commercial fields, especially in environments with strict water quality requirements. Through a series of optimized designs and technical applications, stainless steel reverse osmosis systems have shown the characteristics of high efficiency, stability and low maintenance in the water treatment process.

The core advantage of stainless steel reverse osmosis systems lies in the reverse osmosis membrane technology they use. The reverse osmosis membrane adopts a microporous structure that only allows water molecules to pass through, blocking dissolved salts, heavy metals, bacteria and other harmful substances in the water. Through this physical barrier, the reverse osmosis system can efficiently remove most of the pollutants in the water, greatly improving the efficiency of water purification. Compared with traditional water treatment equipment, reverse osmosis technology can more accurately filter fine impurities in the water and provide a higher purity water source.

As a material, stainless steel itself has extremely strong corrosion resistance and oxidation resistance, and can effectively resist the chemicals in the water and their changes during the water treatment process. Acidic, alkaline or other corrosive substances in water have little effect on stainless steel, which enables stainless steel reverse osmosis systems to operate stably for a long time in various complex water quality environments. Compared with other materials such as plastics, stainless steel is not only more durable, but also better able to maintain the overall structure of the system and prevent leakage or failure caused by corrosion or aging. Therefore, stainless steel RO systems can not only work stably under high load and high pressure environments, but also greatly extend the service life of the equipment and reduce the frequency of equipment replacement and maintenance.

During the reverse osmosis process, a high-pressure pump pushes water through the reverse osmosis membrane. This process is one of the keys to improving water treatment efficiency, because high pressure helps to accelerate the permeation rate of water, thereby increasing the water treatment volume and recovery rate. Through optimized design, modern stainless steel RO systems can complete the filtration of large amounts of water in a shorter period of time, reduce wastewater discharge and improve water utilization efficiency. At the same time, the high-pressure design in the system ensures a higher water permeability during the filtration process and achieves higher water treatment efficiency.

Cleaning and maintenance of stainless steel RO machines are also one of the key factors to improve their water treatment efficiency. The reverse osmosis membrane will affect the filtration effect due to the accumulation of scale or pollutants, while the surface of stainless steel equipment is smooth and easier to clean. Compared with other materials, stainless steel is easier to clean and maintain, reducing downtime and labor cleaning costs. Regular cleaning helps keep the system running efficiently and avoids the decline in treatment efficiency due to pollution accumulation.

English

English 中文简体

中文简体