-

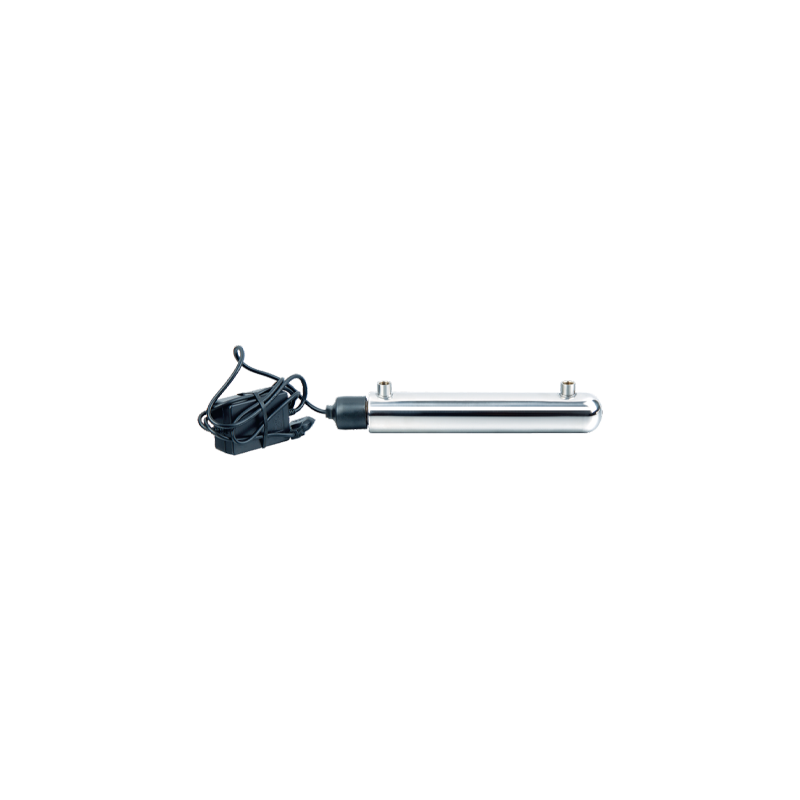

UV11W High-efficiency Intelligent UV Water Sterilizer Cat:Ultraviolet Water Sterilizer

UV11W High-efficiency Intelligent UV Water Sterilizer Cat:Ultraviolet Water SterilizerThe UV11W High-efficiency Intelligent UV Water Sterilizer is an advanced water purification system that offers convenience and reliability. This steri...

See Details -

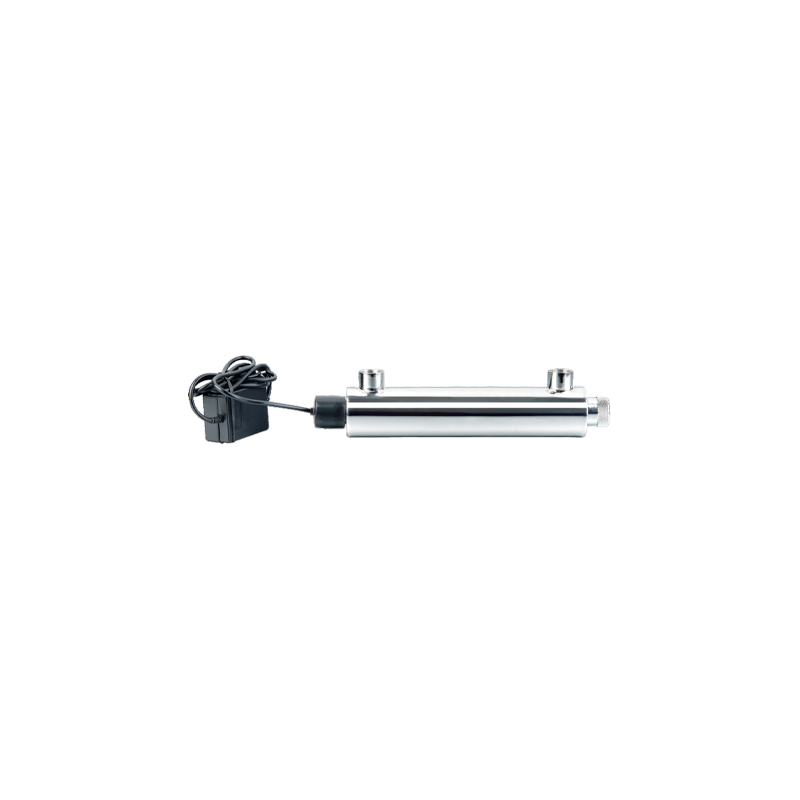

UV16W-A Household Stainless Steel UV Water Sterilizer Cat:Ultraviolet Water Sterilizer

UV16W-A Household Stainless Steel UV Water Sterilizer Cat:Ultraviolet Water SterilizerThe UV16W-A Household Stainless Steel UV Water Sterilizer is an innovative solution for ensuring safe and pure water in your home. Designed with durab...

See Details -

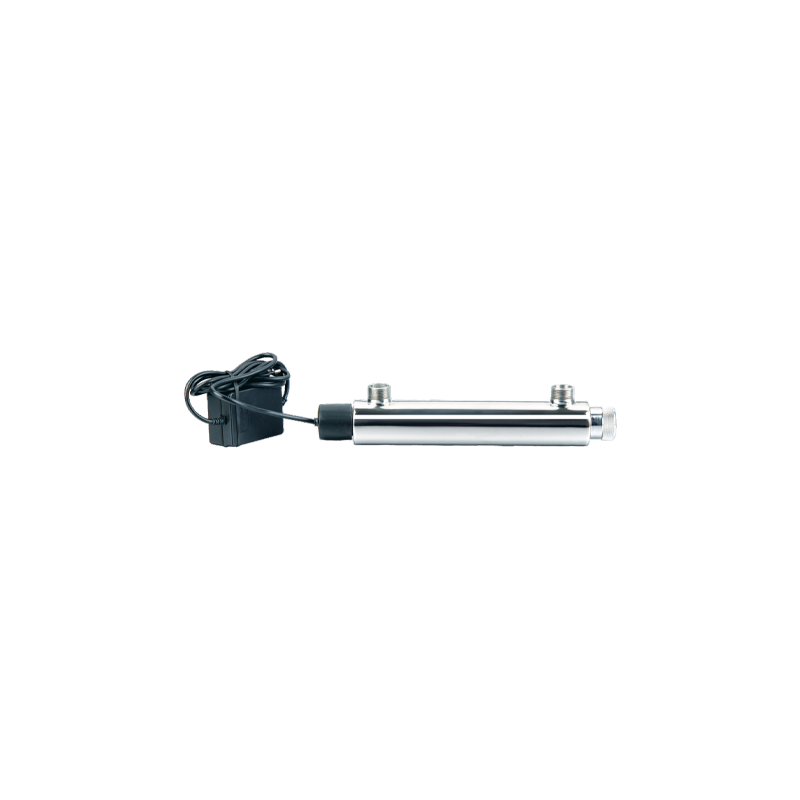

UV16W-B 304 Stainless Steel Water Purifier Ultraviolet Water Sterilizer Cat:Ultraviolet Water Sterilizer

UV16W-B 304 Stainless Steel Water Purifier Ultraviolet Water Sterilizer Cat:Ultraviolet Water SterilizerUV16W-B 304 Stainless Steel Water Purifier Ultraviolet Water Sterilizer is an efficient water treatment equipment based on advanced ultraviolet disinf...

See Details -

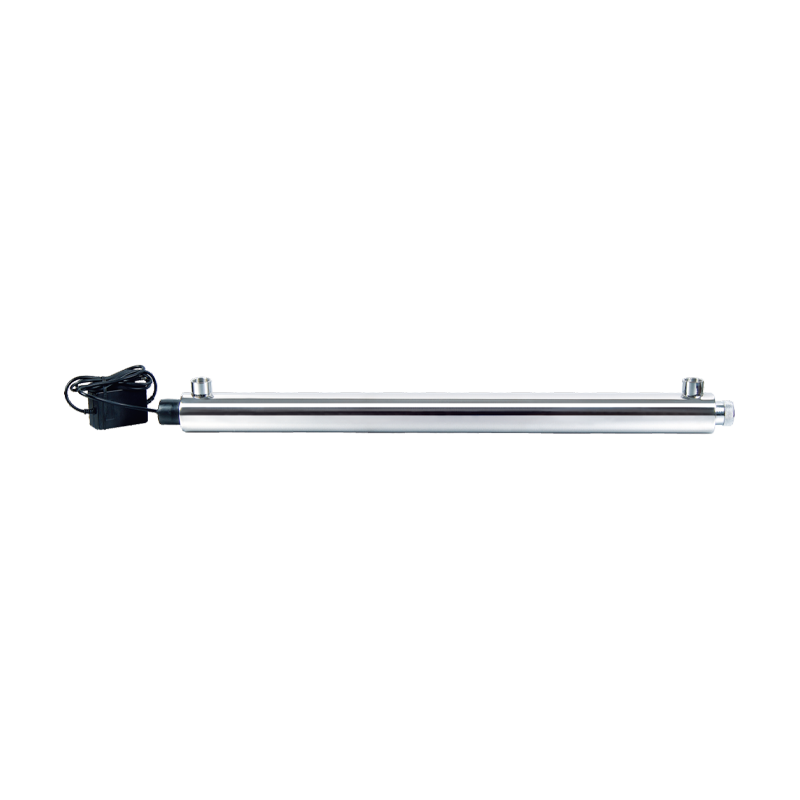

UV25W Stainless Steel Ultrafiltration Pre-Filtration UV Sterilizers For Water Cat:Ultraviolet Water Sterilizer

UV25W Stainless Steel Ultrafiltration Pre-Filtration UV Sterilizers For Water Cat:Ultraviolet Water SterilizerUV25W Stainless Steel Ultrafiltration Pre-Filtration UV Sterilizers For Water uses high-quality stainless steel materials, which have superb corrosion...

See Details -

UV30W-55W Automatic Ultraviolet Sterilizer UV Filtration For Drinking Water Cat:Ultraviolet Water Sterilizer

UV30W-55W Automatic Ultraviolet Sterilizer UV Filtration For Drinking Water Cat:Ultraviolet Water SterilizerThe core advantage of UV30W-55W Automatic Ultraviolet Sterilizer UV Filtration For Drinking Water lies in its efficient and rapid disinfection capabil...

See Details -

TQ-R03 Stainless Steel Booster Double Water Full Effect RO Water Purifier Cat:Stainless Steel Ro System

TQ-R03 Stainless Steel Booster Double Water Full Effect RO Water Purifier Cat:Stainless Steel Ro SystemTQ-R03 Stainless Steel Booster Double Water Full Effect RO Water Purifier is a household water purification device that combines efficient water purif...

See Details -

TQ-R05 Multifunctional Water Purification Source RO Water Purifier Cat:Stainless Steel Ro System

TQ-R05 Multifunctional Water Purification Source RO Water Purifier Cat:Stainless Steel Ro SystemThe TQ-R05 Multifunctional Water Purification Source RO Water Purifier is an advanced, versatile water purification solution designed for households a...

See Details -

TQ-R06 Stainless Steel Environmentally Friendly RO Water Purifier Cat:Stainless Steel Ro System

TQ-R06 Stainless Steel Environmentally Friendly RO Water Purifier Cat:Stainless Steel Ro SystemThe TQ-R06 Stainless Steel Environmentally Friendly RO Water Purifier combines advanced RO filtration technology, durable stainless steel housing, and...

See Details -

Stainless Steel Pure Double Water Pipe Water Purifier Cat:Stainless Steel Pipeline Water Purifier

Stainless Steel Pure Double Water Pipe Water Purifier Cat:Stainless Steel Pipeline Water PurifierThe Stainless Steel Pure Double Water Pipe Water Purifier is an advanced water purification system designed to provide dual-mode purified water with e...

See Details -

TQ-R08 Stainless Steel High-Flow RO Water Filter Cat:Stainless Steel Ro System

TQ-R08 Stainless Steel High-Flow RO Water Filter Cat:Stainless Steel Ro SystemThe Stainless Steel High-Flow RO Water Filter (TQ-R08) provides a powerful and effective solution for purifying drinking water, combining advanced rev...

See Details

Widespread Application of Stainless Steel Reverse Osmosis Systems in the Food and Beverage Industry

With the continuous development of the global food and beverage industry, water quality requirements are becoming increasingly stringent. This is especially true in the production process, where water is not only a primary raw material but also plays a crucial role in multiple processes, such as cleaning and disinfection. The quality of the water source directly impacts food safety, taste, and consumer health. Therefore, ensuring that water quality during production meets industry standards has become a major challenge for food and beverage companies. Due to its high efficiency and durability, the stainless steel reverse osmosis system has become a core technology for addressing water quality issues. Using advanced reverse osmosis technology, this system efficiently removes harmful substances such as dissolved salts, organic matter, and bacteria from water, ensuring that water meets the most stringent safety standards and thus safeguarding the quality of food and beverages.

Technical Advantages of the Stainless Steel Reverse Osmosis System

1. Highly Efficient Water Purification: The stainless steel reverse osmosis system utilizes the filtration principle of reverse osmosis membranes to remove over 99% of impurities such as dissolved inorganic salts, heavy metals, suspended solids, bacteria, and viruses from water. Ensuring the safety and purity of water used in the production of drinking water, beer, and beverages is crucial. The efficient filtration capabilities of RO membranes ensure that water quality meets food safety and hygiene standards.

2. Corrosion Resistance of Stainless Steel: Stainless steel not only offers excellent corrosion resistance but also withstands harsh operating environments such as high temperatures and high pressures. Water treatment equipment in food and beverage production must maintain stable operation despite frequent and prolonged use. The corrosion resistance of 316 stainless steel enables long-term, trouble-free operation of reverse osmosis systems, reducing equipment maintenance costs and improving system stability and reliability.

3. Energy Saving and Environmental Protection: Stainless steel reverse osmosis systems not only effectively remove impurities but also efficiently recycle water, improving water utilization. Compared to traditional distillation and other water treatment methods, RO systems consume less energy and operate stably at lower operating pressures, offering significant advantages in energy conservation and environmental protection.

4. Intelligent Control and Automation: Modern stainless steel reverse osmosis systems are equipped with intelligent automatic control systems that monitor water quality and equipment operating status in real time, automatically adjusting the water treatment process. If a system anomaly or water quality substandard occurs, the intelligent system will promptly issue an alarm or make adjustments, ensuring that water quality consistently meets requirements throughout the production process.

|

Model number |

TQ-R01 |

|

Filter element configuration |

PP + UDF + PP + RO + CTO |

|

Water pressure range |

0.1~0.4Mpa |

|

Water quality requirements |

Municipal tap water |

|

Water outlet mode |

Single water and double water can be selected |

|

Product size |

508 * 160 * 403mm |

|

Pressure barrel |

3.2G |

|

Temperature range |

4-38℃ |

|

Rated net water flow rate |

0.2 L/min |

|

Core element alarm device |

Yes |

|

Supercharging, self-priming |

Pressurization, and self-priming can be selected |

|

Core element alarm device |

Yes |

Applications of Stainless Steel Reverse Osmosis Systems in the Food and Beverage Industry

With increasing emphasis on food safety and production efficiency, more and more food and beverage companies are adopting stainless steel reverse osmosis systems to ensure water quality in production and improve overall production efficiency.

1. Drinking Water and Mineral Water Production: Drinking water and mineral water production places extremely stringent water quality requirements, particularly the removal of impurities and harmful substances. Traditional water treatment technologies cannot fully meet these high standards. However, stainless steel reverse osmosis systems can effectively remove dissolved salts, bacteria, chlorine, fluoride, and other substances from water, ensuring that the quality of production water meets drinking water standards. In particular, RO systems can remove impurities from mineral water while preserving its minerals and maintaining its natural flavor.

2. Beer and soft drink production: In the beer and soft drink production process, water is not only used to prepare the beverage itself but also in cleaning, disinfection, and packaging. Water quality directly impacts the taste, flavor, and safety of the product. Stainless steel reverse osmosis systems can effectively remove odors, impurities, and harmful substances from water, ensuring stable and high-quality water quality throughout the production process. In beer production, the dechlorination function of RO water effectively prevents the impact of chlorine on the brewing process and preserves the flavor of the beer.

3. Water treatment in food processing: In food processing, water is widely used for cleaning raw materials and sterilizing equipment. A stainless steel reverse osmosis system ensures the purity of cleaning and disinfection water, thereby preventing food contamination during processing and packaging. For example, during the washing of vegetables and fruits, water treated by an RO system can remove bacteria and harmful substances, ensuring food safety and hygiene.

4. Water treatment needs in the dairy and pharmaceutical industries: The dairy and pharmaceutical industries have particularly stringent requirements for water quality. In the dairy production process, stainless steel reverse osmosis systems ensure water purity and hygiene, preventing contaminants from affecting product quality. In the pharmaceutical industry, RO systems remove microorganisms, bacteria, and chemicals from water, ensuring that water used in production meets GMP (Good Manufacturing Practice) standards and safeguards pharmaceutical production safety.

5. Industrial cleaning and equipment disinfection: Water cleanliness plays a crucial role not only in the production process but also in equipment cleaning and disinfection. Using reverse osmosis-treated water prevents contamination of production equipment, extending equipment life and reducing maintenance. In food and beverage production, in particular, the quality of cleaning and disinfection water determines the sanitation of the production environment, thereby ensuring product safety.

6. Water conservation and wastewater treatment: Food and beverage companies often consume significant amounts of water during their production processes. Stainless steel reverse osmosis systems offer significant advantages in wastewater treatment and water recycling. RO systems can effectively remove dissolved salts, suspended solids, and harmful substances from wastewater, effectively recycling and reusing water resources. This not only reduces water waste in the production process, but also reduces the company's operating costs and environmental burden.

English

English 中文简体

中文简体