-

UV11W High-efficiency Intelligent UV Water Sterilizer Cat:Ultraviolet Water Sterilizer

UV11W High-efficiency Intelligent UV Water Sterilizer Cat:Ultraviolet Water SterilizerThe UV11W High-efficiency Intelligent UV Water Sterilizer is an advanced water purification system that offers convenience and reliability. This steri...

See Details -

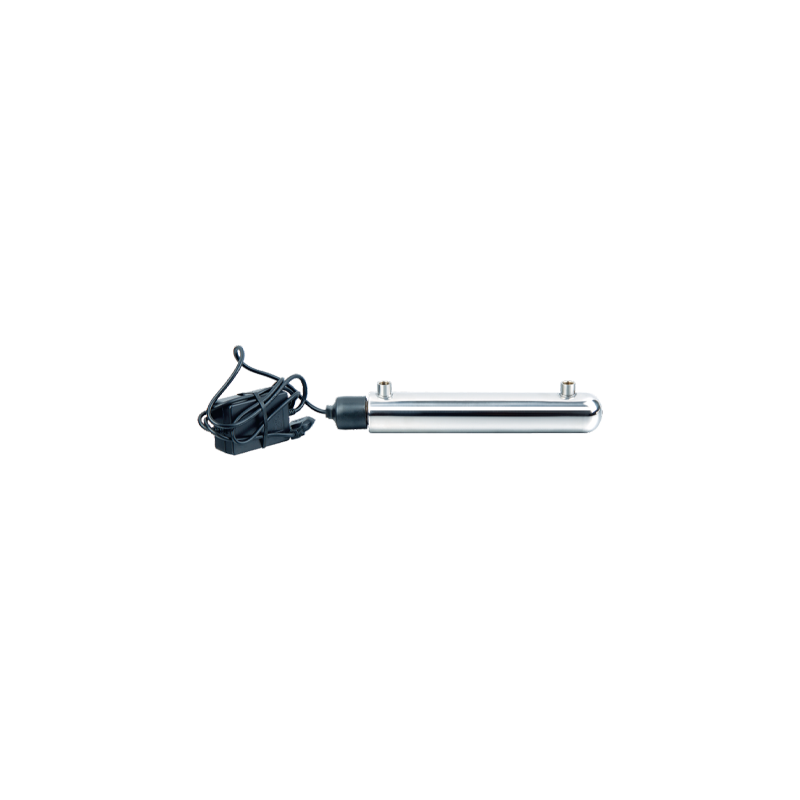

UV16W-A Household Stainless Steel UV Water Sterilizer Cat:Ultraviolet Water Sterilizer

UV16W-A Household Stainless Steel UV Water Sterilizer Cat:Ultraviolet Water SterilizerThe UV16W-A Household Stainless Steel UV Water Sterilizer is an innovative solution for ensuring safe and pure water in your home. Designed with durab...

See Details -

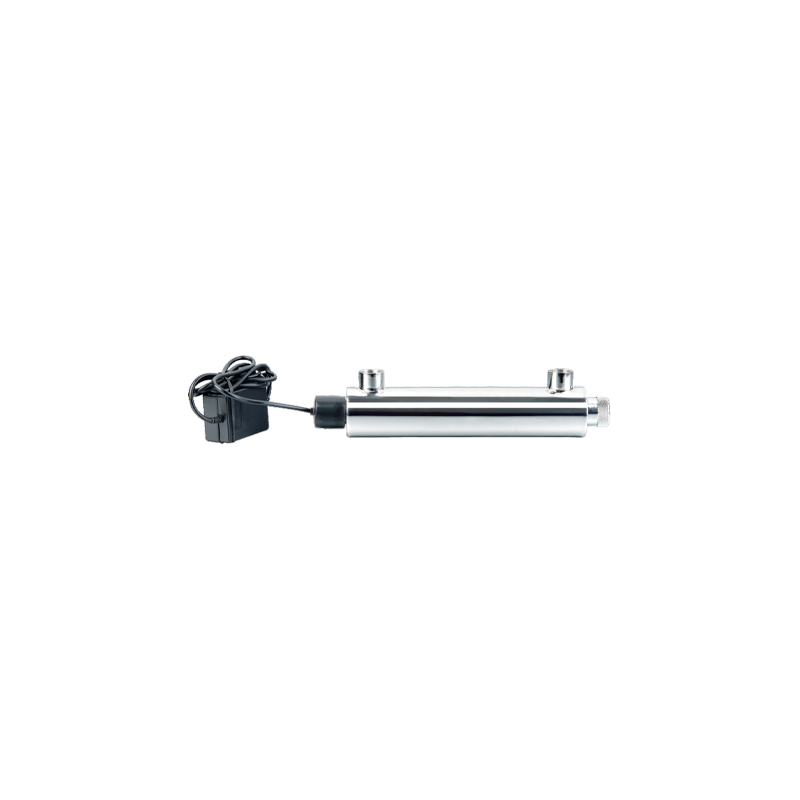

UV16W-B 304 Stainless Steel Water Purifier Ultraviolet Water Sterilizer Cat:Ultraviolet Water Sterilizer

UV16W-B 304 Stainless Steel Water Purifier Ultraviolet Water Sterilizer Cat:Ultraviolet Water SterilizerUV16W-B 304 Stainless Steel Water Purifier Ultraviolet Water Sterilizer is an efficient water treatment equipment based on advanced ultraviolet disinf...

See Details -

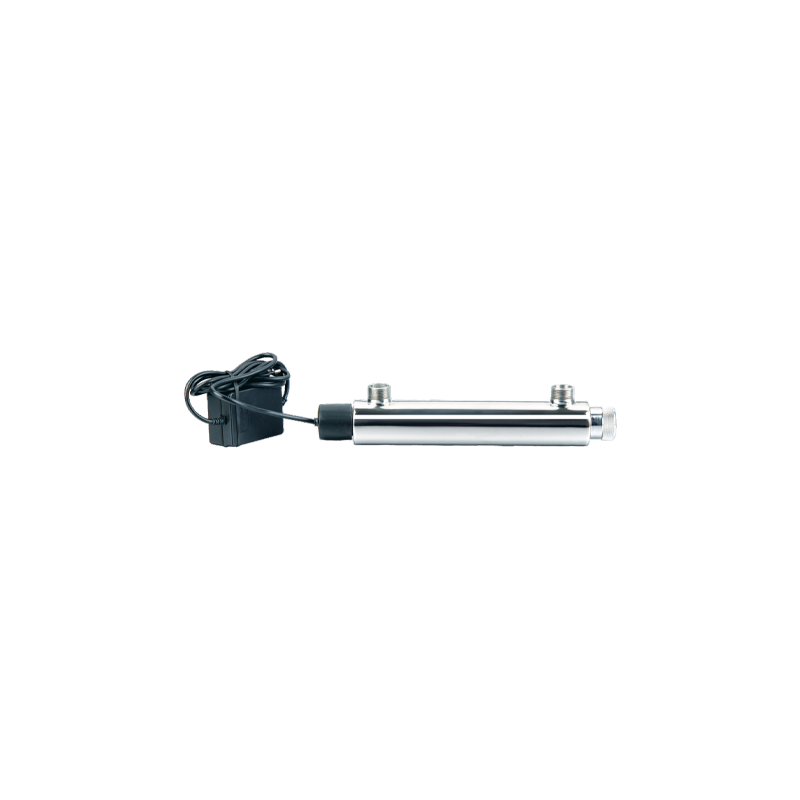

UV25W Stainless Steel Ultrafiltration Pre-Filtration UV Sterilizers For Water Cat:Ultraviolet Water Sterilizer

UV25W Stainless Steel Ultrafiltration Pre-Filtration UV Sterilizers For Water Cat:Ultraviolet Water SterilizerUV25W Stainless Steel Ultrafiltration Pre-Filtration UV Sterilizers For Water uses high-quality stainless steel materials, which have superb corrosion...

See Details -

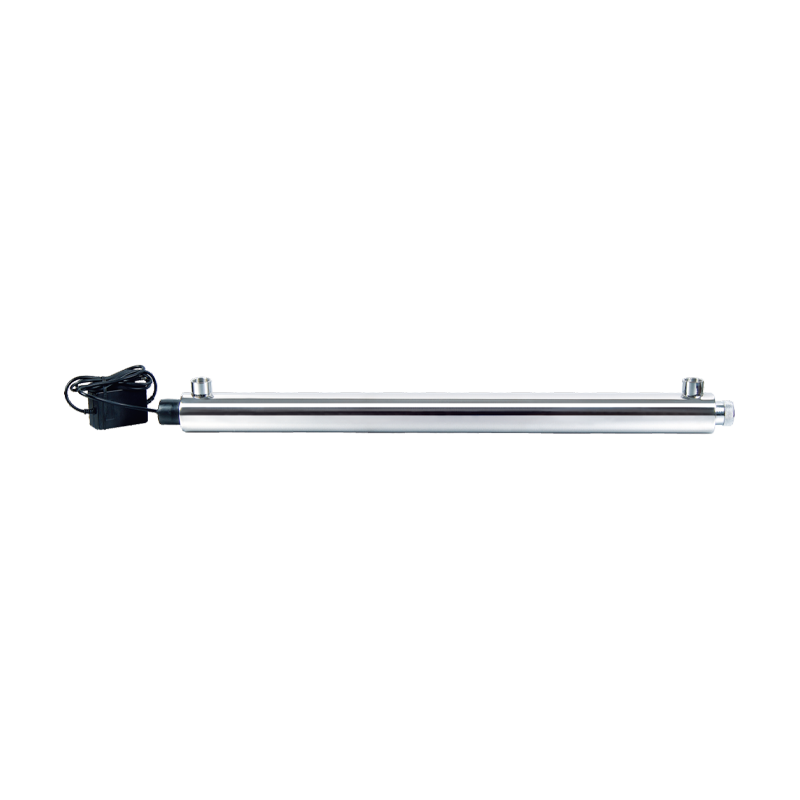

UV30W-55W Automatic Ultraviolet Sterilizer UV Filtration For Drinking Water Cat:Ultraviolet Water Sterilizer

UV30W-55W Automatic Ultraviolet Sterilizer UV Filtration For Drinking Water Cat:Ultraviolet Water SterilizerThe core advantage of UV30W-55W Automatic Ultraviolet Sterilizer UV Filtration For Drinking Water lies in its efficient and rapid disinfection capabil...

See Details -

TQ-R03 Stainless Steel Booster Double Water Full Effect RO Water Purifier Cat:Stainless Steel Ro System

TQ-R03 Stainless Steel Booster Double Water Full Effect RO Water Purifier Cat:Stainless Steel Ro SystemTQ-R03 Stainless Steel Booster Double Water Full Effect RO Water Purifier is a household water purification device that combines efficient water purif...

See Details -

TQ-R05 Multifunctional Water Purification Source RO Water Purifier Cat:Stainless Steel Ro System

TQ-R05 Multifunctional Water Purification Source RO Water Purifier Cat:Stainless Steel Ro SystemThe TQ-R05 Multifunctional Water Purification Source RO Water Purifier is an advanced, versatile water purification solution designed for households a...

See Details -

TQ-R06 Stainless Steel Environmentally Friendly RO Water Purifier Cat:Stainless Steel Ro System

TQ-R06 Stainless Steel Environmentally Friendly RO Water Purifier Cat:Stainless Steel Ro SystemThe TQ-R06 Stainless Steel Environmentally Friendly RO Water Purifier combines advanced RO filtration technology, durable stainless steel housing, and...

See Details -

Stainless Steel Pure Double Water Pipe Water Purifier Cat:Stainless Steel Pipeline Water Purifier

Stainless Steel Pure Double Water Pipe Water Purifier Cat:Stainless Steel Pipeline Water PurifierThe Stainless Steel Pure Double Water Pipe Water Purifier is an advanced water purification system designed to provide dual-mode purified water with e...

See Details -

TQ-R08 Stainless Steel High-Flow RO Water Filter Cat:Stainless Steel Ro System

TQ-R08 Stainless Steel High-Flow RO Water Filter Cat:Stainless Steel Ro SystemThe Stainless Steel High-Flow RO Water Filter (TQ-R08) provides a powerful and effective solution for purifying drinking water, combining advanced rev...

See Details

How to Extend the Lifespan of a Stainless Steel Pre-Filter?

Stainless steel pre-filters are essential industrial equipment, widely used in a variety of industries, including water treatment, air purification, chemicals, food processing, and machinery manufacturing. Their primary function is to initially filter impurities from fluids or gases, protecting downstream equipment from contaminants and particulate matter, thereby ensuring efficient and stable system operation. Stainless steel pre-filters are susceptible to wear, clogging, and corrosion in long-term, high-load, and highly polluted environments, shortening their service life. Therefore, effectively extending the lifespan of stainless steel pre-filters has become a critical issue for companies.

Content

- 1 Working Principle and Importance of Stainless Steel Pre-Filters

- 2 Effective Measures to Extend the Lifespan of Stainless Steel Pre-Filters

- 2.1 Regular Inspection and Cleaning: Ensure Efficient Filter Operation

- 2.2 Optimizing Operating Load: Preventing Overloading and Excessive Wear

- 2.3 Regularly Replace the Filter Element: Ensure Filtration Effectiveness

- 2.4 Selecting the Appropriate Cleaning Method: Avoiding Damage to the Stainless Steel

- 2.5 Controlling the Operating Environment: Slowing Down Equipment Aging

- 2.6 Proper Installation and Transportation: Avoiding External Impact

- 2.7 Selecting a High-Quality Pre-Filter: Ensuring Equipment Durability

Working Principle and Importance of Stainless Steel Pre-Filters

Stainless steel pre-filters use their unique mesh structure to initially filter larger particles and impurities from fluids or gases, preventing these contaminants from entering downstream precision equipment or systems, thereby preventing clogging, corrosion, and damage. Due to the high mechanical strength, corrosion resistance, and high-temperature resistance of stainless steel, pre-filters can operate for long periods in harsh environments, providing reliable protection.

The importance of a stainless steel pre-filter lies not only in its protective effect on equipment but also in its ability to improve overall system efficiency. By removing impurities, the filter ensures the proper functioning of downstream equipment such as fine filters and ultrafilters, reducing equipment failures and lowering maintenance costs. Furthermore, efficient filtration ensures the stable quality of systems like water treatment and air purification, ensuring that production processes are free from contamination.

Effective Measures to Extend the Lifespan of Stainless Steel Pre-Filters

Regular Inspection and Cleaning: Ensure Efficient Filter Operation

Regular inspection and cleaning are the most fundamental methods for extending the lifespan of a stainless steel pre-filter. Over time, impurities and sediment accumulate on the filter mesh, clogging the pores and reducing filtration effectiveness. If not cleaned promptly, the clogged pores not only impair filtration performance but also accelerate filter wear, shortening its service life.

Companies should regularly inspect and clean filters based on the operating environment and pollutant concentration. Generally, filters in the water treatment and gas filtration industries are recommended to be cleaned monthly or quarterly. During cleaning, use a high-pressure water jet or specialized equipment to remove dirt from the mesh surface and maintain unobstructed pores. Avoid using sharp or rough tools during cleaning to prevent scratching the stainless steel mesh and affecting its performance.

For pre-filters in highly polluted environments, chemical cleaning can also be used, but be sure to use a cleaning agent that is non-corrosive to stainless steel to avoid chemical damage to the filter.

Optimizing Operating Load: Preventing Overloading and Excessive Wear

The operating load of a stainless steel pre-filter directly impacts its service life. During operation, filters must operate within a certain flow rate and pressure range. Overloading can cause excessive clogging or wear of the filter mesh, accelerating equipment aging and potentially causing failure. To extend the life of the pre-filter, operators should control the filter's operating load according to the equipment's design requirements and avoid overloading.

Regularly monitoring flow and pressure to ensure the filter operates within its safe operating range can also effectively prevent damage caused by overloading. Particularly in the water treatment and chemical industries, filters often handle high concentrations of impurities or particulate matter. Overloading can lead to poor filtration performance. Therefore, proper load management is crucial.

Regularly Replace the Filter Element: Ensure Filtration Effectiveness

Although stainless steel pre-filters are made of durable materials, the filter mesh will gradually age, wear, or crack over time. Regularly replacing the filter element is crucial. Replacing the filter element not only maintains the filter's high filtration performance but also prevents damaged elements from further affecting the equipment's operation.

Regularly inspect the filter mesh for cracks, blockages, or damage, and promptly replace any damaged filter elements to ensure continued efficient operation. If significant wear or corrosion is observed on the filter mesh during cleaning, consider replacing the filter element to avoid damaging the system's operation due to damaged mesh.

Selecting the Appropriate Cleaning Method: Avoiding Damage to the Stainless Steel

Different types of contaminants affect stainless steel pre-filters differently. Using the appropriate cleaning method can extend the filter's lifespan. In the water treatment industry, high-pressure water jets are commonly used for cleaning, effectively removing sediment and dirt from the water. For air filters, compressed air or a vacuum cleaner can be used to remove dust and fine particles. If the filter is stubbornly contaminated, a specialized chemical cleaner can be used. However, when selecting a cleaning agent, ensure it is non-corrosive to stainless steel. Excessively strong cleaning agents may damage the filter surface, affecting its long-term performance.

Controlling the Operating Environment: Slowing Down Equipment Aging

The operating environment of a stainless steel pre-filter significantly impacts its service life. In environments with high temperatures, high corrosiveness, or high pollutant concentrations, filters experience rapid wear and corrosion. To extend the life of the equipment, companies should control the filter's operating environment, avoiding extreme temperature fluctuations and exposure to highly corrosive gases or liquids.

For example, in industries like the petrochemical industry, filters often operate in high-temperature, highly corrosive environments. Companies can take measures, such as coating the filter with a corrosion-resistant coating or incorporating a temperature control system into the operating environment, to ensure stable operation within a suitable temperature range, thereby slowing down equipment aging.

Proper Installation and Transportation: Avoiding External Impact

The installation and handling of the filter also have a direct impact on its service life. During installation, overtightening or loosening may compromise the filter's seal, affecting its filtration performance. Overtightening may also cause the equipment to deform under pressure, compromising its overall structural stability.

During handling, avoid rough handling to prevent impacts or scratches on the filter, especially on the mesh surface. For large filters, specialized handling equipment should be used to ensure safe handling.

Selecting a High-Quality Pre-Filter: Ensuring Equipment Durability

Selecting a high-quality pre-filter is essential for extending its service life. Stainless steel pre-filters are available in a wide variety of styles and varying in quality. Companies should choose high-quality filters that meet industry standards based on their needs. High-quality filters are typically made of high-quality stainless steel and undergo special corrosion- and high-temperature-resistant treatments, ensuring stable performance over long-term use.

Selecting filters that meet internationally certified standards ensures reliable protection in harsh environments, extends filter life, and reduces unnecessary replacement and repair costs.

English

English 中文简体

中文简体